Spiders are nature’s master engineers, creating one of the most remarkable materials on Earth. Their silk is five times stronger than steel by weight, yet incredibly elastic and versatile. When you see a spider web glistening with morning dew, you’re looking at an engineering feat that humans have yet to fully replicate despite centuries of trying.

Specialized Silk Factories Inside Tiny Bodies

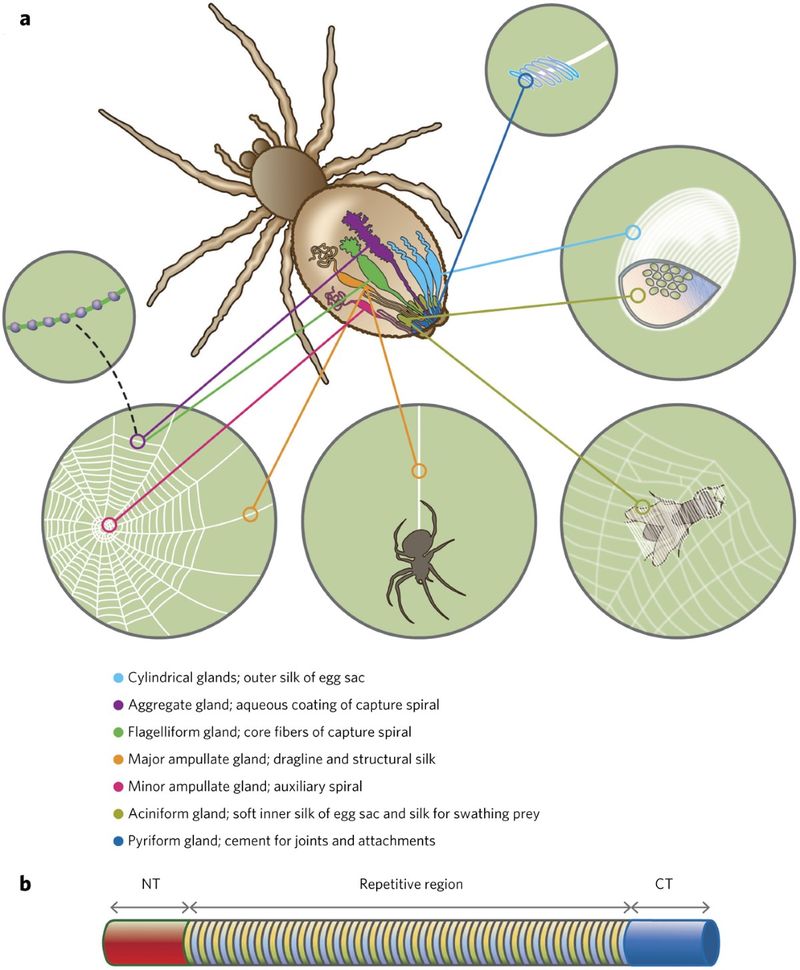

Hidden within a spider’s abdomen lies an impressive array of silk-producing glands, each designed for a specific purpose. Major ampullate glands create the strong dragline silk that forms the web’s framework, while flagelliform glands produce the stretchy capture spiral that snares prey. Some spiders possess up to seven different types of silk glands!

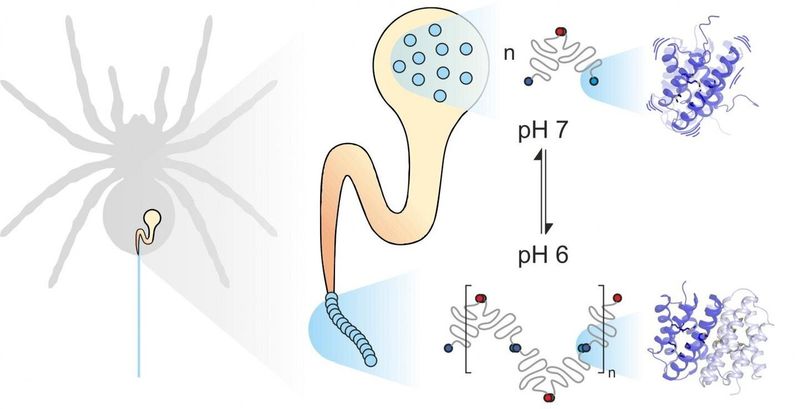

The liquid silk starts as a protein solution called spidroin, stored in specialized sac-like organs. As this liquid travels through narrowing ducts, proteins realign and lock together through hydrogen bonding. The transformation is similar to what happens when you stretch silly putty – except the resulting material outperforms most man-made fibers.

Amazingly, spiders can control silk thickness, strength, and stickiness depending on their needs. This natural production system operates at room temperature using only water as a solvent, making it remarkably environmentally friendly.

Nature’s Spinning Machine: The Spinneret

At the business end of a spider’s silk-making system are the spinnerets – finger-like appendages that work like precision nozzles. Most spiders have multiple pairs of these remarkable organs located at their rear end, each containing hundreds of microscopic spigots. The spider uses its back legs to draw out the silk while controlling which spinnerets activate.

Spider spinnerets aren’t just passive tubes. They actively participate in the silk’s final properties by adding tension at precisely the right moment. This stretching process aligns protein molecules, dramatically enhancing the silk’s strength.

What makes spinnerets truly remarkable is their versatility. A spider can switch between producing dragline, capture spiral, or wrapping silk almost instantly. Imagine having a 3D printer that could switch between printing steel, rubber, and adhesive on demand – that’s what spinnerets accomplish!

Molecular Magic: How Liquid Becomes Super-Strong Fiber

The transformation of spider silk from liquid to solid fiber happens in milliseconds through a process engineers still struggle to replicate. Inside the spider’s glands, the silk proteins float in a watery solution with a neutral pH. As this liquid travels through narrowing ducts, something remarkable happens – the pH drops, becoming acidic.

This pH change triggers the protein molecules to fold and link together, forming chains that align parallel to each other. Meanwhile, water molecules are squeezed out as the duct narrows. The physical pulling of the silk by the spider’s legs adds the final touch, stretching these protein chains to create incredible strength.

The molecular structure resembles a combination of crystalline regions (providing strength) connected by amorphous, stretchy sections (providing elasticity). This natural design creates a material that can stop flying insects without breaking, absorbing enormous energy for its weight.

Web Engineering: Building Architectural Marvels

Spider webs aren’t random constructions – they’re carefully engineered structures built with mathematical precision. The orb-weaving spider, for example, creates its iconic spiral web by first establishing a frame of non-sticky dragline silk. These radial spokes connect to surrounding structures and provide the framework for the entire web.

After completing the framework, the spider switches silk types mid-construction. It spirals outward from the center, laying down a temporary scaffolding thread. Then comes the masterstroke – working inward, it replaces this scaffold with sticky capture silk, creating the perfect trap.

Each silk type serves a specific architectural purpose. The frame threads absorb impact energy when prey hits the web, while the sticky spiral threads efficiently capture insects. Most impressive is how spiders adjust their web designs based on available space, prey types, and even weather conditions – true adaptive engineering!

Bio-Inspiration: Learning From Eight-Legged Engineers

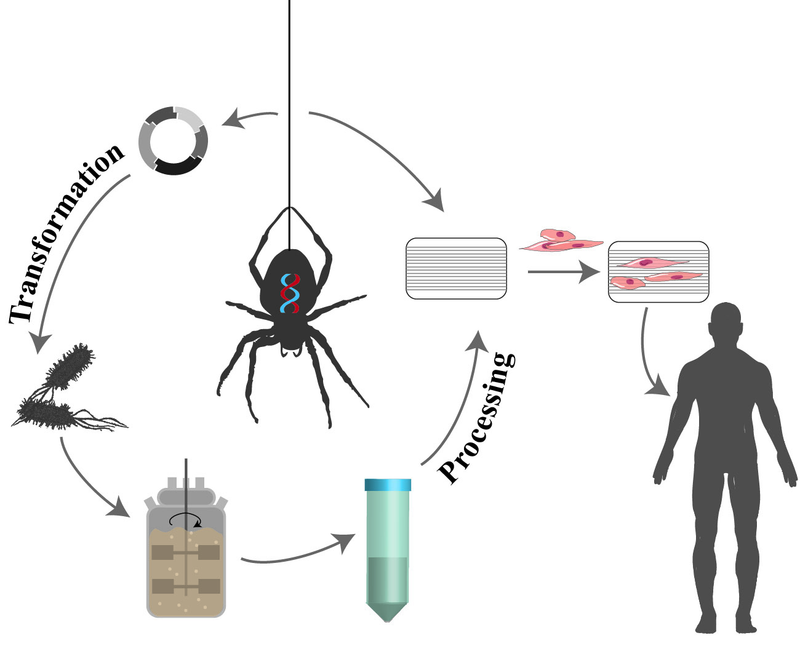

Scientists and engineers are racing to unlock the secrets of spider silk for revolutionary applications. Bulletproof vests made from artificial spider silk could be lighter and more flexible than current options. Medical researchers envision biodegradable sutures and scaffolds for growing replacement tissues and organs – all because spider silk is remarkably compatible with human bodies.

Creating synthetic spider silk has proven challenging. Companies have inserted spider genes into bacteria, yeast, silkworms, and even goats to produce silk proteins, but matching the spinning process remains difficult. The spider’s ability to control protein alignment and water content during spinning creates properties no laboratory has fully replicated.

Beyond materials science, spider web architecture inspires structural engineers designing earthquake-resistant buildings. The web’s ability to absorb energy without breaking offers valuable lessons for creating resilient structures. As we continue studying these eight-legged engineers, their 400-million-year head start in silk production keeps teaching us new lessons.